In order to future proof our buildings and prepare for a 100% renewable energy future, we need to reduce the environmental footprint of our buildings. The easiest and best way to do this is to use the Passivhaus standard as a base point. By improving the performance of our buildings we can reduce the energy use to a level where the requirements for heating and cooling is minimal and can be easily met by the smallest air source heat pumps (referred to from this point as heat pumps) which also happen to be the best performing.

This study will use figures from House 1 at 3 Oakley to illustrate this argument. This house is a very good example of how to build a Passivhaus in Adelaide. All the calculation were worked out in the Passivhaus software PHPP. Because the house produces around 7 times the electricity it consumes and has battery storage, it is likely there will be no need to draw electricity from the grid. The cost of the electricity is therefore based on the 16c per kWh feed in tariff. This rate is used in all calculations.

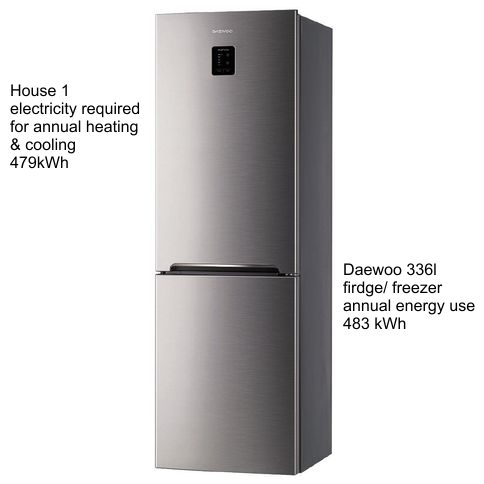

The annual heating and cooling requirement for House 1 is 2,011 kWh. By using 5 star heat pumps which have a stated performance COP of over 5, the system should be able to achieve efficiencies of at least 4.2 COP, so the actual electricity required to heat and cool the house will be 479 kWh (2,011/4.2) in a calendar year. This means the annual cost for heating and cooling will be under $80. To put this in perspective, a 336l Daewoo rcp-307 fridge/ freezer consumes 483 kWh per annum, so the annual heating and cooling cost for this house is about the same as the cost of running an average fridge.

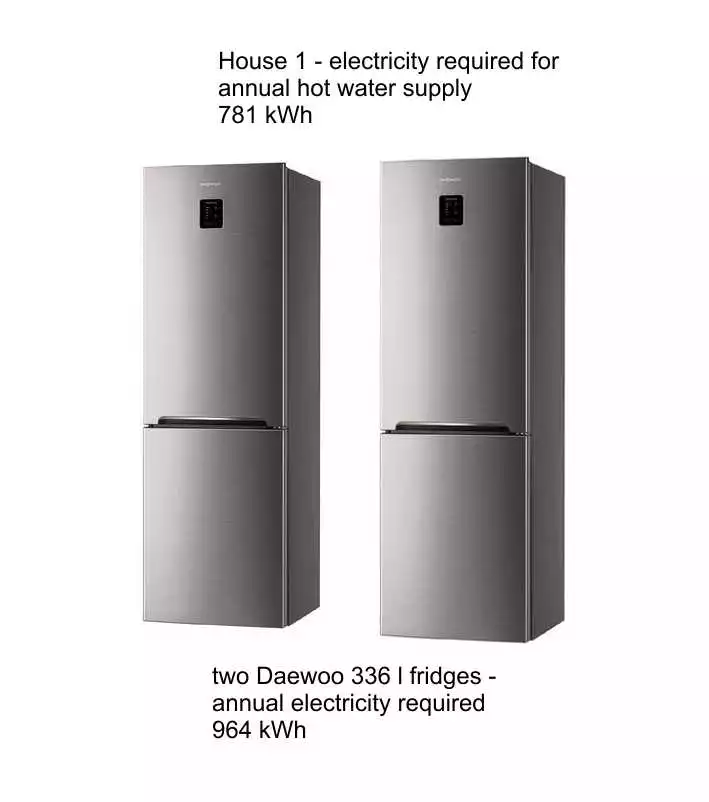

For the domestic hot water system the total requirement as calculated in PHPP, (Passive House Planning Package) based on an internal 323 l storage tank with a heat loss rate of 1.485 w/k, is 3,521 kWh. Some manufacturers claim the COP for the good quality CO₂ heat pumps manufactured in Japan is up to 5.7. The big advantage of using the CO₂ heat pumps is that they perform exceptionally well in cold conditions. PHPP assesses the actual COP performance for the “Reclaim” unit in House 1 to be 4.01. The “Reclaim” unit has a COP of 4.0 at 5°C. This is considered an extreme and rare event in Adelaide so the unit should always perform above this figure. The Reclaim unit also has a smart controller that allows you to set the heat time to 10.00 am so that the unit will only draw electricity from the solar PV system and acts as a form of battery storage because this hot water is available for use when the sun is not shining. This will improves the actual COP because it will usually operate during or near the warmest part of the day. If there is a shortage of hot water there is a boost function that over-rides the settings. Based on this amended usage profile I have used a COP of 4.5. Using this COP figure the annual hot water cost is $125 ((3512/4.5)*.16).

As part of our focus on moving away from the use of fossil fuels and non-renewable energy in order to mitigate the effect of greenhouse gasses, it is important to try to use only renewable electric energy in our homes. We have a moral obligation to do this even if there is a cost penalty associated with that choice. However, this section will look at the raw costs of such a move and ignore the moral component. So the question to ask is how much of a penalty is there in removing gas from our buildings, or is there actually a financial benefit in doing so.

The actual extra cost of installing gas in the home (not including appliance costs) over and above an electric only option, is $3,500 to $5,500 depending on the number of appliances and the pipe run lengths. For a typical gas instantaneous hot water unit we add $1,000 for the supply of the Hot water unit. Annual running costs for this gas system for a 4 person family would be about $1,000 comprising a $285 annual access charge and and a bit over $700 for actual gas used.

If we look at a high quality “Reclaim” CO₂ heat pump with a 315 litre storage tank, the supply and install cost is about $5,500. So if we take the standard cost argument of comparing the heat pump finished cost to the shelf price of a gas instantaneous unit we are down $4,500. Not a good result but still justifiable from a moral viewpoint. However, if we look at the the total gas install and supply cost of $4,500 to $6,500 compared to $5,500 for the electric heat pump option, the costs are comparable. If we then compare the running costs of gas versus heat pump ($1,000 – $125) we are in front by $875 a year when we go with the heat pump option. Even if we ignore the cost of the gas and compare the $285 access charge to the total Passivhaus cost of $205 ($80 + $125) for annual heating, cooling and total hot water, it is $80 cheaper with the all electric option even after including heating and cooling. For House 1 the hot water calculation also includes the hot water used by the dishwasher and the washing machine.

So even ignoring the moral argument, if you were to go with the gas option, your annual costs for hot water would be at least $875 more per annum and your install setup costs would be around the same. So when someone tells you that gas is cheaper, tell ’em they’re dreaming.

We all seem to understand that good quality heat pumps work well in our hot Adelaide summers. However, some people will question their performance in Winter. Some time ago, I was taken aback by a statement made by a person who lives in the Adelaide Hills. She stated that “heat pumps do not work in the Hills, you need gas because it is just too cold”. If we look at the data from Mount Barker in the Adelaide Hills, we find that in the coldest month the mean maximum temperature is 14.3°C and the mean minimum temperature is 6.1°C. If we want to take this data to an extreme the coldest temperature ever recorded in Mount Barker was -1.1°C (34°F). So we can use this as a reference point.

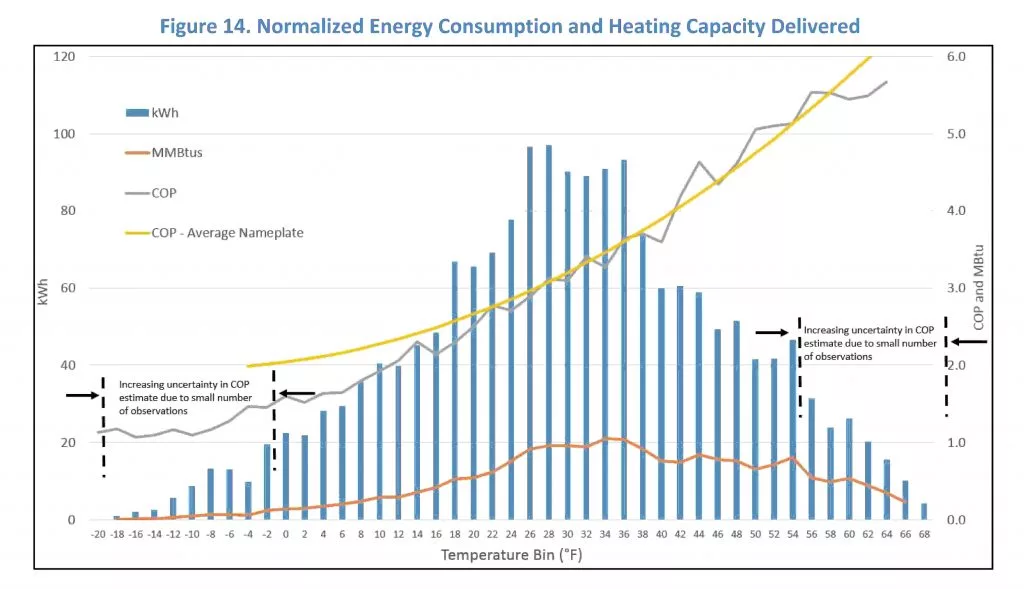

These heat pumps work best in high performance buildings that have a low heat demand, when sized correctly. If I refer to the report “Evaluation of Cold Climate Heat Pumps in Vermont” (link below) table 14 (enclosed) provides a comprehensive overview of the results. This study was undertaken by the Vermont Public Service Department, USA form the beginning in November 2015 through to the 2017 heating season. The study covered in-situ heat pumps usage by metering a total of 77 heat pump systems at 65 unique service accounts. The study takes actual field data and compares it to listed averages performance COP’s of the units. These figures are listed in Figure 14 on page 24 of the report. This graph shows that at 0°C (32°F), the average actual COP of all the units was around 3.3. From a temp of -8°C (17.6°F) starting with a COP of 2.8, as the temperatures continued up to 3.3°C (38°F) COP 3.6, the manufacturers stated COP and actual measured COP the figures were comparable. At -20°C (-4°F) the actual measured COP was around 1.5 which is still significantly better than electric resistance heating performance COP of 1.0. To put things in perspective, The average coldest day of the year in Vermont, January 29, has an average low of -13.3°C (8°F) and high of -3.3°C (26°F). So even on the average coldest day of the year the heat pump will be performing at a COP of 1.85(min) to 2.95(max). Still a very good level of performance for an air source heat pump. If we go back to Mount Barker where the lowest ever recorded temperature was -1.1°C (34°F), a good quality correctly sized heat pump would still deliver COP’s over 3.0 which would be more than adequate.

This is an extract from an article titled “Ellis Passivhaus laughed at Chicago’s Polar Vortex” in treehugger.com written by Lloyd Alter. Link Below.

In January 2019 Chicago experienced a polar vortex that drove outdoor temperatures down to -31°C at night with a maximum of -28°C during the daytime.Over a 34 hour period temperatures averaged -27°C. This presented a good opportunity to assess the performance of the Ellis Passivhaus air source heat pump heating performance. Ellis Passivhaus maintained an interior temperature of > 21.5°C throughout, far above the required 20°C comfort standard. The ERV (energy recovery ventilator) continuously delivered fresh filtered air while retaining > 84% of the energy in the extract air stream. Despite the heating system’s 140 kW per hour rated capacity (48K BTUs), actual use averaged 7,5 kWh per hour (< 26K BTUs) during the 48 hour event or ~ 90% less than comparable Chicago stock all else equal. All systems performed flawlessly. And this is while using a Mitsubishi air source heat pump, when everyone has been saying for years that heat pumps are not efficient at such low temperatures and can’t cope.

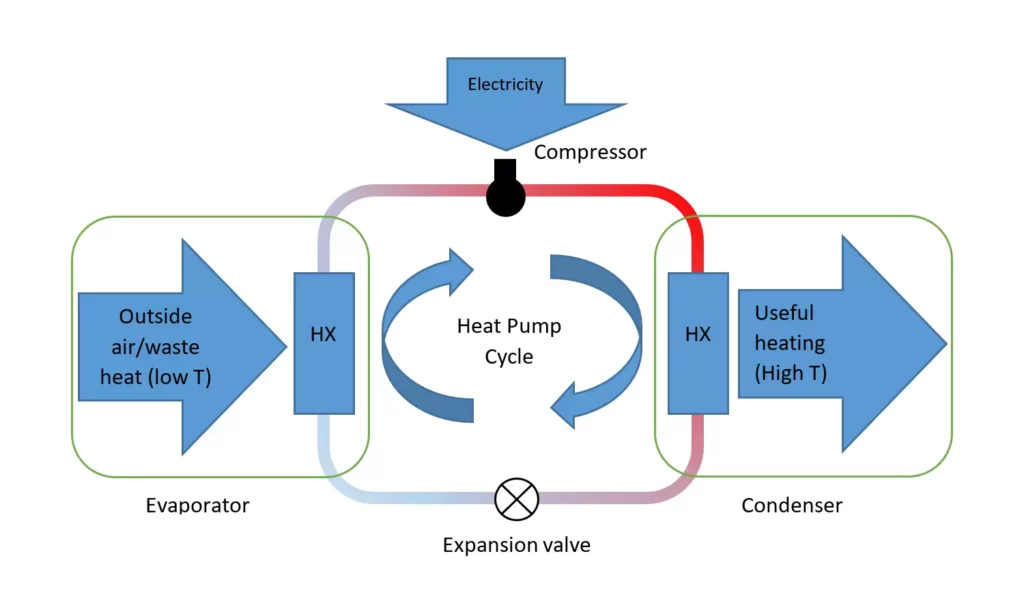

Using natural CO₂ as the refrigerant and achieving a high coefficient of performance (COP), CO₂ heat pumps offer both ecological and financial benefits. Instead of the more conventional R134A refrigerant gases, CO₂ Heat Pumps use super-critical carbon dioxide as the refrigerant. The technology offers a means of energy conservation and reduces the emissions of greenhouse gas. CO₂ is a natural refrigerant and has an ozone depletion potential (ODP) of zero and a global warming potential (GWP) of only 1. CO2 refrigerant is a non HFC refrigerant. Traditional HFC refrigeration systems affect climate change in two distinct ways: direct and indirect contribution. Direct contribution results from the release of refrigerants into the atmosphere. Indirect contribution refers to the energy used to operate traditional refrigeration equipment. The less energy required to operate the equipment, the lower the impact on the environment.

The Reclaim CO₂ heat pump has a smart controller that offers 5 different operation modes and settings. The PV setting mode allows you to maximize the energy your PV system produces to offset hot water energy costs by restricting the operation to daytime. If needed a single shot boost will allow you to heat up the water outside of set times.

Every inch of our homes are not only beautifully designed, they are calculated and built to surpass the World’s most rigorous energy efficiency, comfort and sustainability standards for buildings. Every component, every wall, window and even appliance is taken into consideration when meeting the Passivhaus performance standards

available from 9:00 – 18:00

Address: 21 Beatty St, Flinders Park, South Australia

© Copyright 2023 – All rights reserved